How does Direct Ink Writing work?

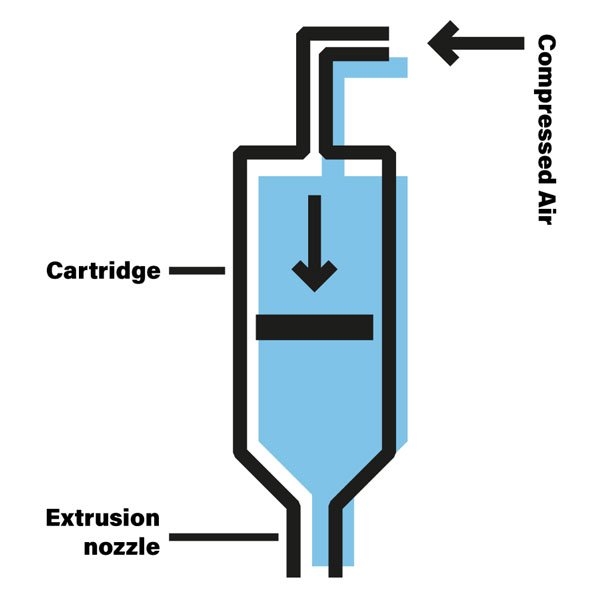

Direct Ink Writing (DIW), also known as “robocasting”, is a cutting-edge additive manufacturing technique that enables the precise deposition of inks or pastes to create complex three-dimensional structures. It functions much like 3D printing but offers greater versatility in terms of materials.

In DIW, a syringe or nozzle dispenses the ink, which can be composed of a variety of materials, including metals, ceramics, polymers, and even biological substances like cells or biocompatible gels. The printer follows a computer-generated design to create intricate and customized objects layer by layer.

Does your material fit our technology?

Materials

Silicone

With a wealth of in-house expertise, our company excels in employing silicone for Direct Ink Writing (DIW) applications. Our successful collaborations with industry partners include printing gasket seals, harsh environment enclosures, thermal-insulating sockets and more.

The utilization of 3D printing with silicone is revolutionizing diverse industries, leveraging silicone’s flexibility, biocompatibility, and durability. For example, in healthcare, medical-grade silicone is enhancing prosthetics and personalized implants, while automotive and aerospace sectors are benefiting from custom gaskets and seals. The process employs various techniques apart from DIW, including direct motor driven extrusion for precise layer-by-layer deposition and the use of silicone-based inks or pastes in inkjet.

Ceramic Paste

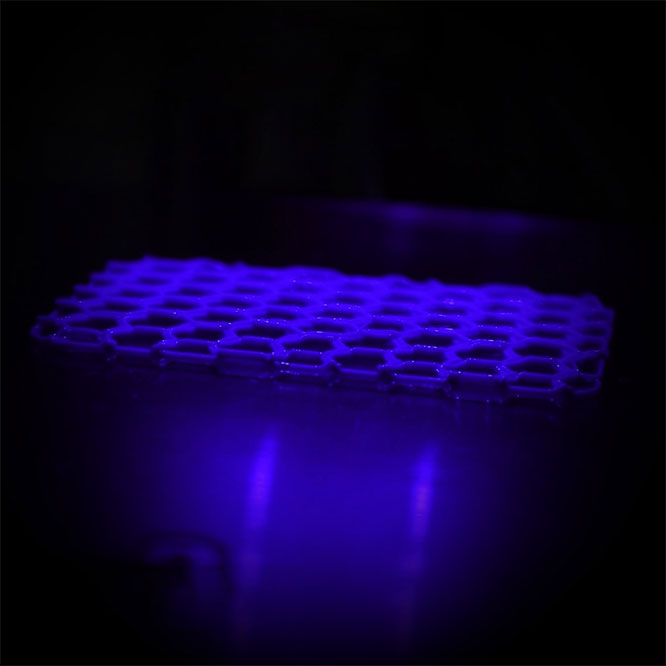

Our company excels in applying ceramic paste for DIW, both in-house and through partnerships. Notably, we formulate our proprietary zeolite-based ceramic paste, offering specialized solutions for design, electronics, and advanced manufacturing applications. Notable examples include solid-phase filters, insulating pipeline enclosures, and washers as well as jewellery components and decorative tiles.

3D printing with ceramics is transforming various industries, capitalizing on ceramics’ renowned qualities such as exceptional heat resistance, mechanical strength, and electrical insulation. Notably, this technology is reshaping aerospace and automotive sectors by producing high-demand items like ceramic turbine blades and engine components, optimizing their performance and efficiency. These advancements in ceramic printing encompass a range of commonly procured items, including intricate ceramics and ceramic pastes. The techniques employed empower designers and engineers to enhance product performance, lower production costs, and explore innovative designs. This transformative technology is set to continue shaping industries and sparking creativity in modern ceramic-based manufacturing.