3D printing with silicones opens a new chapter in thinking about soft robotics, expands the possibilities to achieve complex geometries and speeds up the emergence of scientific breakthroughs.

It’s not just the domain of science – production lines also use a variety of grippers and manipulators. That’s why we have also decided to test the F-NIS – it turns out that it is an excellent machine also for the development of the science of soft robotics.

F-NIS: Transforming Production and Soft Robotics

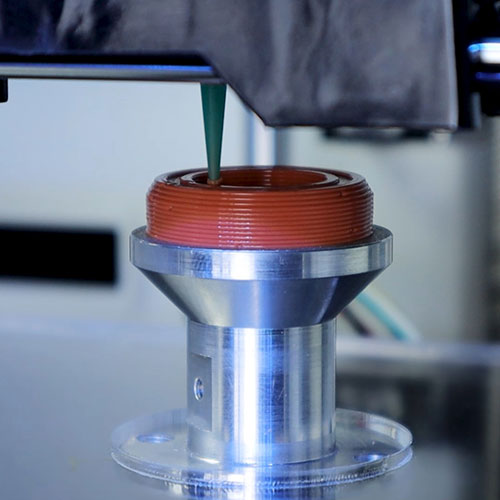

The seamless integration of F-NIS 23151 silicone 3D printing with metal elements represents a revolutionary approach to optimizing production lines. This innovative technology reinforces the reliability and longevity of suction cups and brings about many benefits for the production industry.

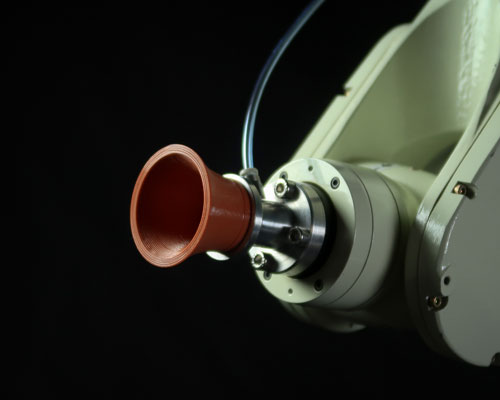

Bellows and calyx suction cups have proven effective according to testing with robotic arms. These tests have showcased their unparalleled ability to meet the dynamic challenges posed by modern production environments. As a result, soft robotics in manufacturing has leaped forward, promising more efficiency, precision, and adaptability.

One of the most notable advantages of F-NIS technology is its compatibility with a wide range of silicone materials. Manufacturers now have the flexibility to choose silicone types that precisely align with their unique production requirements. This adaptability not only enhances the functionality of suction cups but also ensures that production lines can maintain peak performance across various applications.

The benefits of F-NIS extend beyond improved suction cup performance. This groundbreaking technology streamlines production processes, reduces the need for traditional adhesives and assembly parts, and significantly enhances the overall efficiency of production lines. Additionally, F-NIS empowers manufacturers to produce custom molds and components tailored to their specific needs, thus reducing lead times and production costs.

Silicone 3D Printing Across Diverse Surfaces

The F-NIS 23151 is an advanced 3D printing machine that enables the creation of silicone suction cups, among other things. However, it offers much more than that. Thanks to the F-NIS 23151, we can print 3D directly onto metal components, ensuring robust and durable connections through material cross-linking. This breakthrough technology eliminates the need for traditional adhesives and assembly parts, paving the way for a new era in production line efficiency.

Using silicone as a printable material provides tremendous opportunities due to its exceptional elasticity and resistance to various environmental conditions. By F-NIS, we can create not only suction cups but also intricate structures and mechanisms using this revolutionary material.