We tested our F-NIS 23151 printed gripper with a robot arm and an egg. We handled it very carefully, examining the stability and gentleness of the material so as not to damage the delicate load. Incorporating F-NIS into our experiments has revealed its multifaceted capabilities and positioned it as an invaluable tool for promoting progress in the complex landscape of soft robotics.

Precision 3D Silicone Printing with F-NIS: Enhancing Soft Robotics

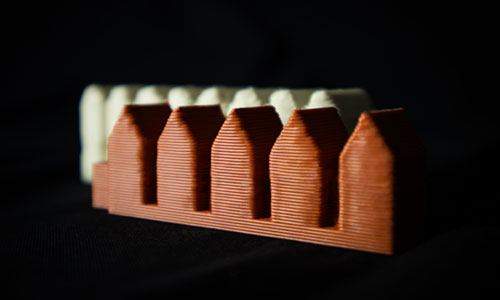

The decision to delve into the capabilities of F-NIS 23151 technology was born out of its impressive adaptability within the scientific community, making it a valuable asset for advancing the field of soft robotics. The potential of 3D silicone printing, propelled by F-NIS, reaches far beyond the confines of academic research. It finds tangible utility in the dynamic domain of soft robotics, where a diverse array of grippers and manipulators is pivotal in optimizing various industrial processes.

The fusion of F-NIS technology with a robotic arm creates a mesmerizing synergy, emphasizing the delicate yet efficient art of manipulation. Through meticulous trials involving an egg, we shed light on the vast potential of this partnership. We carefully navigate the fine line between ensuring a secure grip on fragile cargo and preserving its inherent fragility.

As soft robotics ventures into uncharted dimensions with 3D silicone printing, the adaptable F-NIS technology emerges as a versatile conduit. It serves as a catalyst for scientific advancement and an enabler of innovative solutions within industrial production. Positioned at the intersection of scientific exploration and industrial progress, the collaboration between F-NIS and soft robotics clears the path for groundbreaking research. It enhances the capabilities of production lines through the seamless integration of precision grippers.

New Horizons in Soft Robotics

Embracing 3D printing with silicones heralds a paradigm shift in our perception of soft robotics, unlocking uncharted avenues for realizing intricate forms and catalyzing the rapid emergence of scientific breakthroughs. Beyond its scientific implications, 3D silicone printing resonates powerfully with the realm of production lines. These operational lifelines rely on an eclectic array of grippers and manipulators, where F-NIS emerges as a promising candidate for enhancing gripping efficiency. The fusion of F-NIS technology with a robotic arm introduces a captivating synergy that underscores the essence of delicate yet efficient manipulation. Our trials with an egg illuminate the potential of this union as we carefully navigate the fine line between a secure grip and preserving the fragility of the cargo. As soft robotics ventures into new dimensions with 3D silicone printing, the versatile F-NIS technology emerges as a conduit not only for scientific progression but also as an enabler of advanced solutions for industrial production. Innovating at the crossroads of science and industry, the collaboration between F-NIS and soft robotics not only paves the way for groundbreaking research but also enriches the capabilities of production lines through the integration of precision grippers.

In conclusion, integrating F-NIS technology into 3D silicone printing has proven to be a transformative force in soft robotics and industrial applications. This collaborative journey has showcased the delicate balance between technology and fragility and the potential for F-NIS to revolutionize scientific research and production processes. With precision and care, F-NIS technology is paving the way for a future where soft robotics reaches new heights of efficiency and innovation.