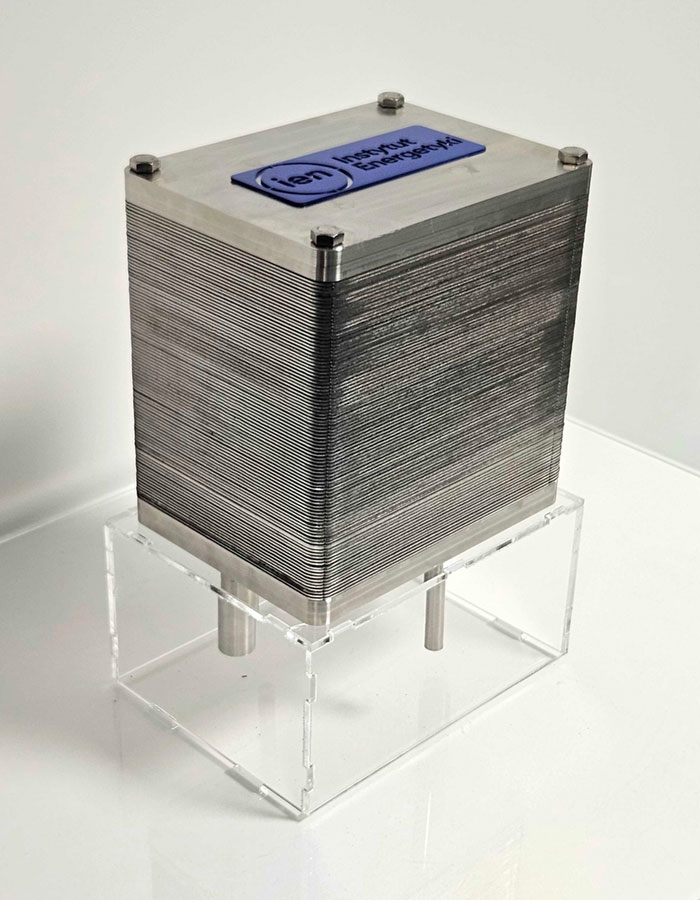

Constructing the stack of solid oxide electrochemical cells

HydroGEN is based on reversible solid oxide electrochemical cells operating alternately according to the power-to-gas (P2G) concept – in electrolyzer (SOE – Solid Oxide Electrolyser) and fuel cell (SOFC – Solid Oxide Fuel Cell) modes. The HydroGEN-based installation was designed and delivered by IEn in form of a container system integrated with EC Elbląg power plant within the Hydrogin project (realized by CBRF Energa Grupa Orlen and IMP PAN).

The sealing elements of the solid oxide cell stacks, manufactured by IEn, were made using a low-cost and waste-free 3D printing method on dedicated E-NIS machines designed and manufactured by Sygnis SA.

The role of seals in the stack

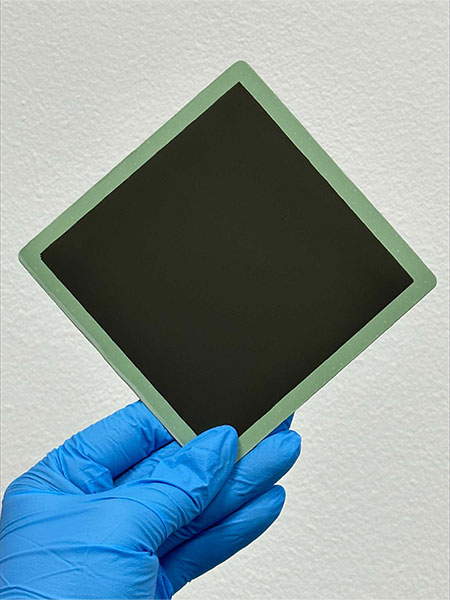

The seal used in order to separate the fuel and air zones inside the device is characterized by an ultra-low gas permeability coefficient. This requirement is met by glass-ceramic seals with strictly defined properties, optimized in the course of multivariate tests, which include: stability in oxidizing and reducing atmospheres over a wide range of partial pressures, resistance to thermal cycling over the life of the stack, compatibility of thermal expansion coefficient values with the parameters of other stack components, electrical insulation (preventing short-circuiting of cells in the stack), chemical compatibility with sealed components, as well as ease of manufacture and low cost.

Patented solution via application of 3D printing

The seals developed at the Institute of Power Engineering are made using an innovative method of 3D printing from glass paste using the E-NIS printers developed and manufactured by Sygnis SA. This is a low-cost and waste-free technology.

The spatial printing technique allows the formation of a glass paste sealing material with appropriate rheological properties directly on the flat and corrugated surfaces of SOC stack elements. It also offers the possibility to build multilayer seals, thus allowing to optimize their thickness according to the application. Direct application of the seal to SOC stack components contributes to the elimination of redundant unit operations in the preparation of glass-ceramic seals and significant time savings, allowing the process to be more efficient and maintain its high repeatability.

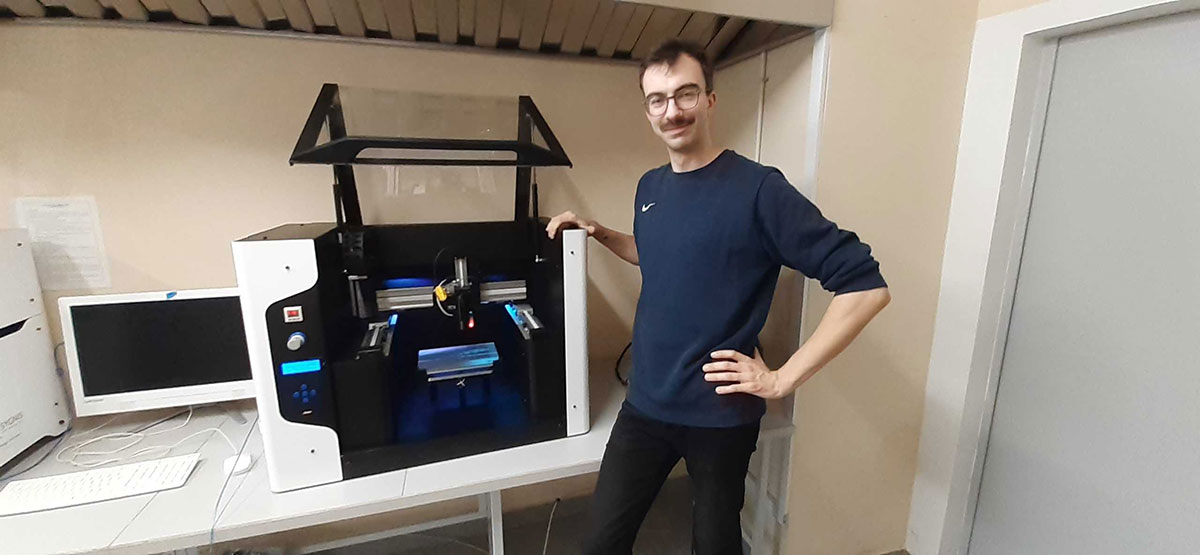

Jakub Malinowski, F-NIS R&D Tech Leader, proudly

delivering the second E-NIS to our partner’s lab

3D printing allows for precise reproduction of the designed shape and ensures high quality and accuracy of the completed print. In addition, the use of waste-free 3D printing technology in the process of forming seals based on solid oxide electrochemical cells allows the production of seals with filler, patented by the Institute of Power Engineering. Such seals provide the required thickness and other gasket properties under equipment operating conditions, and are based on the use of, for example, waste ceramic powders from other industries as a sealing component.

Advantages of SOC technology and the innovative 3D printing technique

An apparent increase in environmental awareness, understanding of the concepts of sustainability and circular economy, and concern for the environment are driving changes in energy policy, both domestically and internationally. SOC technology, in which seal printing technology is implemented, is of key importance due to the highest hydrogen generation efficiency (>92%) among available technologies and the ever-increasing share of RES in the energy mix.

With this technology, excess energy from RES can be efficiently stored in the form of hydrogen, which is a synthetic fuel. The generated hydrogen can be exploited directly in transportation or industry, or as a substrate for alternative fuel production processes (synthetic natural gas – SNG, methanol, synthetic diesel) used in passenger, urban, rail, marine and aviation transportation, fulfilling the sector’s decarbonization strategy. The use of SOC technology is particularly promising in the decarbonization of the chemical, petrochemical, metallurgical and other carbon-intensive industries. The implementation of SOC-based installations makes it possible to reduce CO2 emissions, as well as to increase the energy efficiency of production processes by, among other things, managing heat and waste gases.

Among key industries, heavy industry covers about 75% of its energy needs using fossil fuels, accounting for 20% of global greenhouse gas emissions. In this area, hydrogen as a fuel has significant potential to decarbonize highly carbon-intensive processes, and SOC technology is expected to make a significant contribution to this goal in industry and transportation worldwide.

Prototype installation at final client’s facility, Elbląg

At Sygnis we make the tools for your success

It’s wonderful to see apparent increase in environmental awareness, understanding of the concepts of sustainability and circular economy, and concern for the environment as driving changes in energy policy, both domestically and internationally.

Solid-Oxide Cell technology, in which seal 3D printing technology is implemented, is of key importance due to the highest hydrogen generation efficiency (>92%) among available technologies and the ever-increasing share of RES in the energy mix. Thus, it’s not surprising that The Institute of Power Engineering has already won multiple prizes for the HydroGEN device.

Among their most prestigious prizes up-to-date are:

XXV Polish Product of the Future Award:

Award of the Minister of Climate and Environment:

https://energetab.pl/konkurs-targowy/

GreenEvo:

We wish our IEn partners continued success and awards. They deserve every single one them for their contributions to the sustainable development and revolution of the energy sector. We are happy that our hardware in their hands is helping to shape the future.