Thanks to the ability to print virtually any type of silicone, F-NIS is a perfect tool for printing gaskets of all shapes and sizes. As creators of industrial machines and operators of an additive manufacturing production plant, we ourselves use this capability to produce custom-fit utensils for our needs.

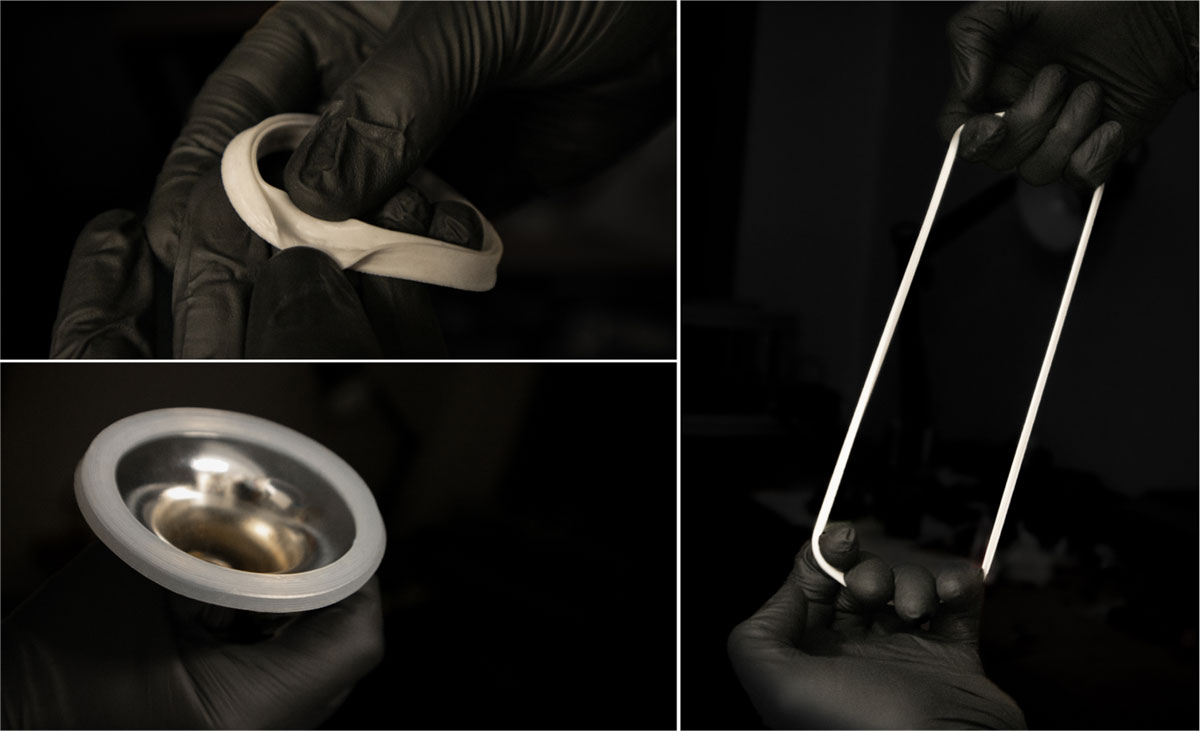

Custom O-rings: Variety and functionality

F-NIS technology allows us to efficiently produce O-rings with complex cross-sections. This capability enables us to meet the specific demands of, for example, the automotive, aerospace, and medical industries, where precise and customized sealing solutions are crucial. By leveraging the flexibility of 3D printing, F-NIS empowers us to iterate and optimize the design of O-rings rapidly. This versatility eliminates the need for molds and production lines, enabling us to create individual functional seals on demand. For instance, we can manufacture industrial silicone seals that meet sanitary standards while maintaining total flexibility despite the layered structure inherent to 3D printing technology. Our iterative approach ensures our clients receive the most effective and reliable sealing solutions for their unique applications.

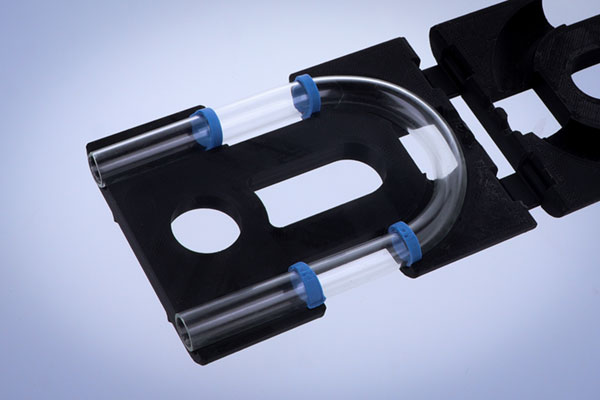

Unconventional applications through precision

Diving into the realm of custom seals tailored for laboratory glassware, F-NIS thrives on delivering precision and adaptability that sets us apart.

Our esteemed clientele includes the Faculty of Chemistry at the University of Warsaw, where we crafted sealing elements and gaskets that match their glass equipment, both the standard and the custom-made, thus preventing any spillage or contamination during chemical processes. What truly distinguishes us is our proficiency in working with an extensive range of silicone materials, allowing us to create seals meticulously calibrated to the specific chemical requirements of each project, regardless of complexity.

Imagine the possibilities

One of the most incredible things about producing sealing elements on F-NIS is the amount of possibilities. It is not limited to simple flat gaskets – the technology is called 3D printing for a reason!

To showcase our versatility, we have curated a gallery of images featuring a wide range of sealing elements. Among these, you’ll discover custom plugs explicitly designed for foundry molds. Handcrafted by our skilled foundry team, these reusable plugs are purpose-built for casting gypsum, seamlessly working with our sturdy frames to streamline the process. These examples are only a few possibilities that highlight our adaptability and problem-solving capabilities.

3D printing is the future of seals

In the fast-evolving technological landscape of today, it’s evident that 3D printing has emerged as the undisputed future of seal manufacturing. At Sygnis we recognize this trend and take immense pride in our pioneering role in pushing the boundaries of what’s possible in this field. We’ve harnessed the power of 3D printing to revolutionize seal production, providing our clients with a level of precision, customization, and efficiency that was once unimaginable.

Our commitment to innovation is unwavering, and we continually invest in cutting-edge technologies and techniques to stay at the forefront of this industry. With our state-of-the-art 3D printing capabilities, we can create seals that are tailored to your specific needs and produced with remarkable precision, consistency, and speed. This allows us to meet tight deadlines and deliver exceptional quality, setting a new standard for seal manufacturing.